Coordinating hazardous materials work in Calgary requires more than booking a single trade. Older buildings, winter humidity swings, and Alberta OH&S asbestos obligations all intersect.

When sampling, removal, and mould remediation happen in silos, scope gaps appear, projects stall, and occupants remain at risk. A unified approach brings together Calgary asbestos testing, mould hygiene controls, and documentation so property teams can make decisions confidently.

This guide outlines how facility directors, condo boards, and restoration companies in Calgary can build an integrated workflow.

From the first phone call to an asbestos abatement contractor Calgary trusts, through clearance air sampling and preventative maintenance, the focus stays on occupant safety. Along the way we highlight practical checkpoints that local inspectors, insurance adjusters, and environmental consultants expect to see on their reports, plus how to leverage resources like the Calgary asbestos abatement hub for neighbourhood-specific updates.

Map the Building's Risk Profile Before Work Begins

Every integrated response starts with a clear map of risk. Calgary's post-war housing stock hides asbestos in vinyl floor tiles, attic insulation, and mechanical chases, while river valley humidity encourages hidden mould.

Begin with a desktop review of past renovation permits, fire or flood events, and historical lab reports. Pair that with fresh Calgary asbestos testing so decision makers know exactly which materials require controls and how friable they are.

A companion moisture assessment should be completed before walls open.

Hygrothermal readings, thermal imaging, and cavity inspections reveal whether mould remediation in Calgary must be staged alongside removal. Logging the data in one shared project dashboard keeps abatement supervisors, hygienists, and building operators aligned on which rooms need containment, negative air, and future monitoring.

Align Scopes Between Environmental Consultants and Contractors

Once hazards are mapped, scope alignment protects budgets and compliance. Environmental consultants typically write the abatement specification, but contractor field realities influence sequencing.

Schedule an integration meeting where the consultant, the chosen asbestos abatement contractor Calgary relies on, and the restoration general contractor walk the site together. That conversation locks in enclosure sizes, waste routes, and temporary power, preventing rework mid-project.

Documenting those agreements in the same portal that stores lab results and photographs means everyone references one source of truth. Include acceptance criteria for mould clearance sampling, asbestos clearance testing, and reinstatement repairs. When scopes are shared transparently, insurance adjusters approve variations faster because the rationale is tied back to measured data.

Design Containments That Address Both Asbestos and Mould

Calgary winters make pressure differentials tricky, so containment design must balance airtightness with heat retention.

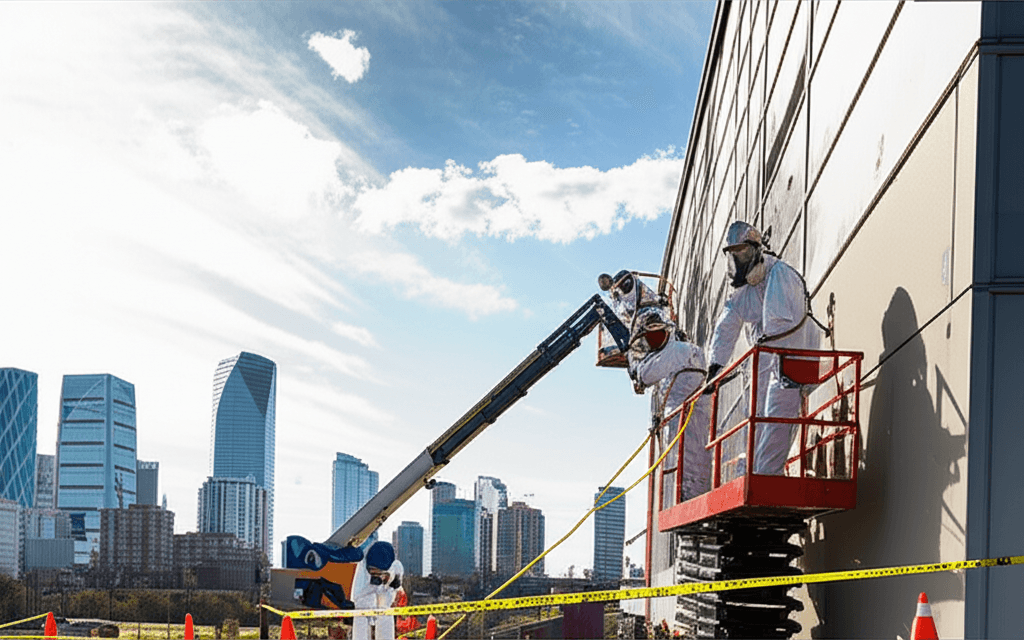

Combine Type 2 or Type 3 asbestos containments with mould remediation zones by using double-door airlocks, supplemental heating, and automated pressure monitors. Place HEPA negative-air machines in positions that support both fibre capture and spore removal, then log readings twice daily to satisfy Alberta OH&S asbestos documentation expectations.

Shared containments also streamline labour. Crews can remove contaminated drywall, bag waste, and immediately HEPA vacuum structural members without breaking down barriers between trades. Just ensure that material staging areas account for longer dwell times caused by mould disinfectant or drying equipment so that sealed waste drums do not block egress paths mandated by Calgary Fire Code.

Sequence Removal to Limit Cross-Contamination

Integrated projects benefit from precise sequencing. Start with gross removal of asbestos-containing materials, such as pipe insulation or vermiculite, following wet removal methods and glove-bag techniques where practical.

Once ACMs are cleared, shift to targeted demolition of water-damaged drywall and subflooring to expose mould colonies. This order keeps mould spores from settling on surfaces awaiting asbestos abatement, reducing the chance of re-cleaning.

Plan for a mid-project inspection with the consultant to verify that substrate moisture readings are trending toward acceptable levels before encapsulation. This is also the point to invite building maintenance teams in for a walkthrough so they understand which mechanical components received insulation replacement or duct cleaning, informing future preventative schedules.

Coordinate Calgary-Focused Air Monitoring

Air monitoring is where integrated projects prove their success. Schedule personal and area air samples that align with both asbestos and mould thresholds.

Alberta laboratories familiar with vermiculite testing Calgary requests can often analyze fibre and spore cassettes from the same shipment, keeping turnaround times tight. Make sure air technicians are briefed on containment zoning so they sample at critical barriers and occupied adjacencies.

When labs return clearance passes, upload them alongside photographic evidence of glove-bag removal, HEPA vacuuming, and surface swab results. Calgary property managers appreciate a consolidated package they can share with tenants or board members, especially when it highlights how asbestos clearance testing and mould clearance criteria were met simultaneously.

Document Alberta OH&S Asbestos Compliance

Integrated documentation simplifies audits. Alberta OH&S asbestos inspectors expect to see hazard assessments, worker competency records, and daily logs.

Combine those with mould remediation checklists into a single compliance binder. Include SDS sheets for encapsulants, disinfectants, and negative-air filters. Having one binder reduces the risk that a required form is left on another subcontractor's truck when officials arrive on-site.

For projects with municipal touchpoints, such as Calgary Building Services permits or insurance claims, append correspondence that shows how specifications complied with CSA Z317.13 and other relevant standards. Highlighting that the same team handled asbestos notification filings and mould work plans assures reviewers that the project met the spirit and letter of the regulations.

Plan Post-Remediation Verification and Re-Occupancy

Once clearance passes are issued, schedule a joint verification walkthrough. Invite the environmental consultant, the mould remediation in Calgary supervisor, and facility representatives to confirm that finishes are ready for reinstatement.

Use moisture meters, borescopes, and differential pressure logs to validate that environmental conditions are stable. This step closes the loop between initial testing, abatement, and restoration.

Provide tenants or staff with a clear re-occupancy memo summarizing containment removal timelines, housekeeping requirements, and any remaining monitoring (such as follow-up humidity checks). A transparent communication plan reduces concerns and demonstrates that leadership prioritizes long-term indoor air quality, not just short-term fixes.

Integrate Preventative Maintenance and Future Testing

An integrated approach does not end when the barriers come down. Feed the data collected during Calgary asbestos removal and mould remediation into the building's asset management plan.

Flag areas that require seasonal humidity monitoring, note which insulation materials were replaced with non-ACM alternatives, and schedule future sampling points. This knowledge transfer keeps future capital projects compliant without repeating the discovery phase.

Consider offering tenants educational materials about spotting condensation, reporting odours, or avoiding DIY disturbances of suspect materials. When occupants understand the warning signs, facility teams receive earlier notice of leaks or damage, allowing them to mobilize trusted abatement partners before issues escalate.

Build a Response Network Before Emergencies Hit

Calgary's spring thaw and summer storm season can trigger emergency calls.

Establish standing agreements with environmental consultants, restoration contractors, and disposal facilities so that sampling, abatement, and mould drying crews can mobilize within hours. Pre-negotiated rates and communication trees reduce administrative delays when multiple units in a condo tower require simultaneous response.

Store contact details, after-hours protocols, and access arrangements in both digital and printed formats. During a power outage or network disruption, teams still need to reference permits, hazard assessments, and supplier availability. Rehearse tabletop exercises that simulate pipe bursts or sprinkler activations to ensure each stakeholder knows how integrated response works under pressure.

Conclusion

Calgary building owners who coordinate testing, abatement, and mould controls as one workflow minimize disruption and protect the people who rely on their spaces. Integrated planning helps teams avoid duplicated labour, meet Alberta OH&S asbestos requirements, and defend budget decisions with clear data. Most importantly, it shortens the path from hazard discovery to safe re-occupancy.

With a documented playbook, your organization can respond quickly the next time a ceiling tile tests positive for chrysotile or a roof leak dampens insulation. Aligning consultants, contractors, and maintenance staff turns a complex scenario into a manageable sequence of steps that keep Calgary families, tenants, and staff healthy.

Need professional mould remediation?

Request a mould inspection or call 403-392-2803 to coordinate with Makki Abatement's certified team.