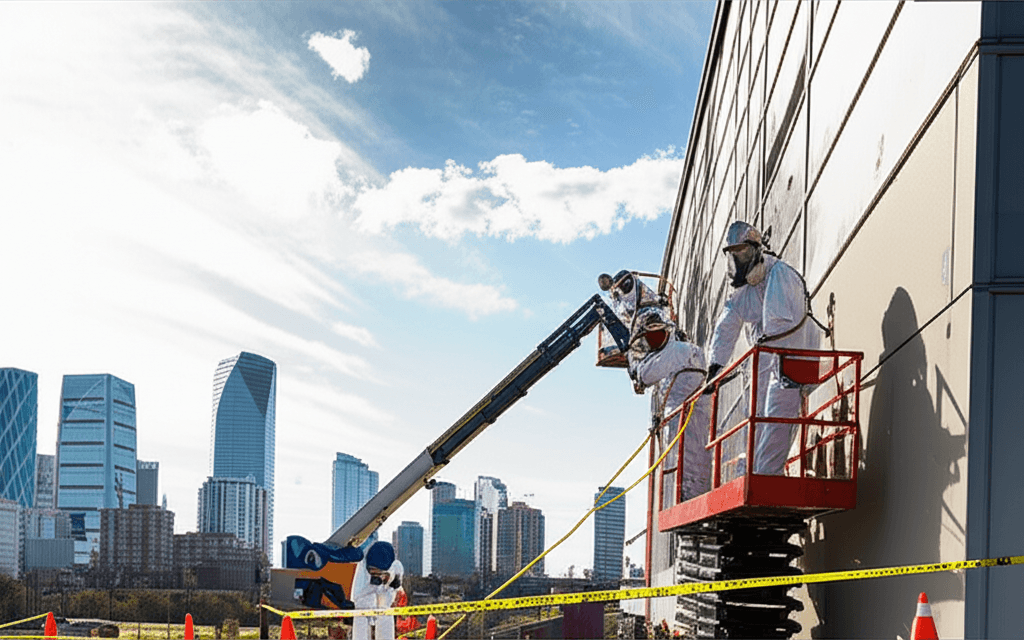

Demolition and renovation projects in older buildings present significant hazardous materials risks that can endanger workers, occupants, and the environment.

Asbestos, lead paint, mould, PCBs, and other toxic substances were commonly used in construction before health risks were understood. Disturbing these materials without proper precautions can cause serious health consequences, legal penalties, and project delays.

This comprehensive safety checklist guides property owners, contractors, and project managers through identifying hazardous materials, ensuring regulatory compliance, implementing safety protocols, and protecting everyone involved in demolition and renovation work.

Pre-demolition planning and assessment

1. Building history research

Before any demolition or renovation work begins, research your building's history:

- • Determine construction date: Buildings constructed before 1990 likely contain asbestos; pre-1978 likely contain lead paint

- • Review building records: Obtain original construction documents, renovation permits, and previous hazardous materials assessments

- • Identify additions and renovations: Document when different sections were built or modified

- • Research building use history: Industrial, commercial, or specialized uses may indicate specific hazards

- • Interview previous owners/occupants: Gather information about known hazards or past remediation work

2. Comprehensive hazardous materials survey

Conduct professional surveys for all potential hazards:

Asbestos survey

- • Hire certified asbestos inspector: Engage qualified professional with appropriate certifications (CSA Z94.4 in Canada, EPA-approved in US)

- • Inspect all suspect materials: Include ceiling texture, floor tiles, insulation, pipe wrap, roofing, siding, drywall compound, adhesives

- • Collect bulk samples: Sample each homogeneous material type and location

- • Laboratory analysis: Use accredited laboratories for polarized light microscopy (PLM) analysis

- • Obtain detailed report: Document locations, material types, asbestos content percentages, and risk classifications

For comprehensive asbestos information, see our complete asbestos removal guide.

Lead-based paint survey

- • Test all painted surfaces: Assume presence in pre-1978 buildings until proven otherwise

- • Use certified lead inspector: Required for rental properties and federally funded projects

- • XRF testing or laboratory analysis: X-ray fluorescence provides immediate results; lab analysis is definitive

- • Test each substrate and layer: Different paint layers may contain varying lead levels

- • Document all locations: Map areas with lead content ≥0.5% (Canada) or ≥1.0 mg/cm² (US)

Mould assessment

- • Visual inspection: Look for visible mould growth, water stains, and moisture damage

- • Moisture testing: Use moisture meters to identify hidden water intrusion

- • Air and surface sampling: Conduct testing if mould is suspected but not visible

- • Identify water sources: Find and document all current and historical moisture sources

- • Assess extent: Determine affected area size and contamination severity

Learn the differences between mould and asbestos in our guide on mould vs. asbestos.

Other hazardous materials

- • PCBs (Polychlorinated biphenyls): Test caulking, adhesives, fluorescent light ballasts (pre-1979)

- • Mercury: Identify thermostats, switches, fluorescent tubes, gauges

- • Ozone-depleting substances: Survey refrigeration equipment, fire suppression systems, insulation foam (pre-1996)

- • Radioactive materials: Check for smoke detectors, exit signs, old gauges containing radium or tritium

- • Silica: Assess potential for crystalline silica exposure during concrete/masonry cutting

- • Wood preservatives: Test for creosote, pentachlorophenol, arsenic compounds in structural timber

3. Regulatory compliance review

Ensure compliance with all applicable regulations:

- • Identify applicable regulations: Federal, provincial/state, and municipal requirements

- • Obtain required permits: Demolition permits, asbestos abatement permits, lead work permits

- • Submit notifications: Occupational health and safety notifications, EPA/environmental agency notifications

- • Verify contractor licenses: Ensure all contractors hold required certifications and insurance

- • Review insurance requirements: Confirm adequate liability coverage for hazardous materials work

- • Document compliance: Maintain complete records of all permits, notifications, and certifications

Hazardous materials abatement planning

4. Develop abatement scope and schedule

- • Prioritize hazards: Address asbestos before other work that might disturb materials

- • Sequence abatement: Plan order of operations (typically: asbestos → lead → mould → other hazards)

- • Coordinate contractors: Schedule hazardous materials contractors before demolition crews

- • Plan phasing: Determine if project can be phased to maintain partial occupancy

- • Establish timelines: Account for testing, permitting, abatement, clearance, and inspection durations

- • Build in contingency: Add 10-20% time buffer for unexpected discoveries or delays

5. Select qualified contractors

Vet all contractors thoroughly:

- • Verify certifications: CSA Z94.4 (asbestos), lead-safe certifications, mould remediation credentials

- • Confirm insurance: Minimum $2-5 million liability, workers' compensation, pollution liability

- • Check references: Contact recent clients with similar projects

- • Review safety records: Request incident rates and regulatory compliance history

- • Evaluate equipment: Verify contractors have proper containment systems, HEPA equipment, PPE

- • Obtain written proposals: Detailed scope, methodology, timeline, and pricing

- • Compare multiple bids: Obtain 3-5 quotes for significant projects

6. Occupant protection plan

- • Notify all occupants: Provide written notice of hazards, work schedule, and safety measures

- • Establish relocation plan: Arrange temporary housing for occupants if required

- • Create communication protocol: Regular updates on project progress and any changes

- • Post warning signs: Clearly mark all hazardous areas and restricted zones

- • Secure site access: Prevent unauthorized entry to work areas

- • Plan re-occupancy: Define criteria and process for safe return after clearance

Site preparation and safety measures

7. Containment and isolation

- • Install physical barriers: 6-mil polyethylene sheeting for walls, floors, ceilings

- • Create airtight seals: Tape all joints, penetrations, and edges

- • Establish negative air pressure: HEPA-filtered negative-air machines (minimum 4 air changes/hour)

- • Build decontamination stations: Three-stage chambers (dirty room, shower, clean room) for worker entry/exit

- • Isolate HVAC systems: Seal vents and ducts to prevent contamination spread

- • Protect adjacent areas: Additional barriers for occupied spaces and sensitive equipment

- • Install air monitoring: Real-time monitoring to verify containment effectiveness

8. Personal protective equipment (PPE)

Ensure all workers have appropriate PPE:

Respiratory protection

- • Asbestos work: Full-face respirators with P100 filters (minimum) or supplied-air systems for Type 3 work

- • Lead work: Half-face or full-face respirators with HEPA filters (P100)

- • Mould work: N95 respirators (minimum) for small jobs; P100 for extensive contamination

- • Fit testing: Annual fit testing for all respirator users

- • Medical clearance: Medical evaluations confirming workers can safely wear respirators

Protective clothing

- • Disposable coveralls: Tyvek or similar suits for asbestos, lead, and mould work

- • Gloves: Nitrile or latex for hazmat work; leather for demolition

- • Boot covers: Disposable covers over work boots

- • Head covering: Hoods or head covers for extensive contamination

- • Eye protection: Safety goggles or face shields

9. Equipment and tools

- • HEPA vacuums: Industrial HEPA-filtered vacuums for cleanup (never use standard shop vacs)

- • Negative-air machines: Sufficient capacity for containment size (calculate CFM requirements)

- • Wetting equipment: Sprayers and wetting agents for dust suppression

- • Hand tools: Manual removal tools that minimize dust generation

- • Air monitoring equipment: Real-time particulate monitors or professional sampling equipment

- • Decontamination supplies: Shower facilities, clean water supply, waste collection

- • Packaging materials: 6-mil polyethylene bags, labels, tape, disposal containers

Abatement execution and monitoring

10. Work practice controls

- • Use wet methods: Keep materials saturated during removal to minimize dust

- • Minimize mechanical disturbance: Avoid power tools that generate dust when possible

- • Remove materials intact: Keep materials whole rather than breaking/crushing when feasible

- • Continuous HEPA vacuuming: Vacuum surfaces regularly during work

- • Immediate bagging: Double-bag waste immediately after removal

- • Maintain negative pressure: Continuously monitor and maintain negative air differential

- • Control access: Strictly enforce decontamination procedures for all entries/exits

11. Air monitoring

- • Baseline monitoring: Establish pre-work air quality in adjacent areas

- • Personal monitoring: Worker breathing zone samples to verify exposure levels

- • Area monitoring: Samples inside containment to assess work practices

- • Perimeter monitoring: Verify containment effectiveness at boundaries

- • Real-time monitoring: Continuous particulate monitoring during high-risk activities

- • Document results: Maintain records of all monitoring data

- • Take corrective action: Address any elevated readings immediately

12. Waste handling and disposal

- • Proper packaging: Double-bag in 6-mil polyethylene bags; seal with duct tape

- • Clear labeling: Mark all bags with hazard type and warnings

- • Secure staging: Store bagged waste in containment or secure area until disposal

- • Transport compliance: Follow TDG/DOT regulations for hazardous waste transport

- • Approved disposal: Use only designated asbestos landfills or hazardous waste facilities

- • Chain of custody: Maintain waste manifests tracking material to final disposal

- • Disposal receipts: Obtain certified receipts confirming proper disposal

Post-abatement verification

13. Final cleaning

- • HEPA vacuum all surfaces: Walls, floors, ceilings, fixtures—everything in containment

- • Wet wipe all surfaces: Damp cloths capture remaining particles

- • Repeat as needed: Multiple cleaning passes may be required

- • Remove gross contamination: All visible debris and waste materials removed

- • Clean equipment: HEPA vacuum and wet wipe all equipment before removal

- • Visual inspection: Verify no visible residue remains

14. Clearance testing

- • Hire independent hygienist: Third-party clearance testing (not the abatement contractor)

- • Visual inspection: Professional inspection confirming thorough cleaning

- • Aggressive air sampling: Use fans/leaf blowers to agitate dust during sample collection

- • Adequate sample number: Minimum samples based on containment size and regulations

- • Laboratory analysis: PCM or TEM analysis for asbestos; appropriate methods for other hazards

- • Meet clearance criteria: Results must be below regulatory thresholds ( Written clearance letter: Obtain formal clearance documentation before re-occupancy

- • Failed test protocol: If testing fails, re-clean and re-test at contractor expense

15. Documentation and record-keeping

- • Pre-work documentation: Photographs, test reports, permits, notifications

- • Daily work logs: Activities performed, materials removed, waste quantities

- • Air monitoring results: All personal, area, and clearance sampling data

- • Waste manifests: Complete chain-of-custody documentation

- • Disposal receipts: Certified receipts from approved disposal facilities

- • Clearance certificates: Written clearance letters from independent hygienists

- • Post-work photographs: Document completed work and site condition

- • Permit closures: Final inspections and permit closure confirmations

- • Permanent records: Maintain all documentation with property files indefinitely

Special considerations

16. Emergency response procedures

- • Develop emergency plan: Written procedures for containment breaches, injuries, fires

- • Emergency contacts: List of emergency services, regulatory agencies, management

- • First aid supplies: Appropriate medical supplies and trained personnel on-site

- • Fire safety: Fire extinguishers, evacuation routes, coordination with fire department

- • Spill response: Containment and cleanup procedures for accidental releases

- • Communication plan: Notification procedures for emergencies affecting occupants or neighbors

17. Multi-hazard projects

When multiple hazards are present:

- • Prioritize asbestos: Remove asbestos before work that might disturb other materials

- • Coordinate containment: Design containment meeting requirements for all hazards present

- • Sequential abatement: Typically asbestos → lead → mould → other hazards

- • Combined PPE: Use most protective equipment required for any hazard present

- • Comprehensive testing: Clearance testing for all hazards before re-occupancy

18. Occupied building considerations

- • Enhanced isolation: Extra containment barriers between work areas and occupied spaces

- • Pressure monitoring: Continuous monitoring of pressure differentials

- • HVAC coordination: Adjust ventilation systems to prevent cross-contamination

- • Off-hours work: Schedule high-risk activities during unoccupied periods

- • Occupant communication: Regular updates on work progress and safety measures

- • Access control: Strict enforcement preventing occupant entry to work areas

Regulatory compliance final checklist

19. Pre-work compliance

- • All required permits obtained and displayed

- • Regulatory notifications submitted (EPA, OH&S, municipal)

- • Contractor licenses and insurance verified

- • Worker certifications confirmed

- • Medical surveillance programs in place

- • Respiratory protection program established

- • Written safety plans prepared and reviewed

- • Waste disposal arrangements confirmed

20. Post-work compliance

- • Clearance testing completed and passed

- • Waste disposal documentation received

- • Final inspections passed

- • Permits closed

- • All required records compiled and stored

- • Occupant notification of completion

- • Post-project debrief conducted

Conclusion: Safety is non-negotiable

Demolition and renovation projects involving hazardous materials require meticulous planning, qualified professionals, appropriate safety measures, and strict regulatory compliance. This checklist provides a comprehensive framework for managing these complex projects safely and legally.

Key takeaways:

- •Always conduct comprehensive hazardous materials surveys before any demolition or renovation work

- •Hire only certified contractors with appropriate credentials, insurance, and experience

- •Follow proper sequencing—asbestos removal typically comes first

- •Implement rigorous containment, PPE, and work practice controls

- •Conduct independent clearance testing before allowing re-occupancy

- •Maintain complete documentation for legal protection and future reference

Cutting corners on hazardous materials safety puts lives at risk, violates regulations, and creates long-term liability. The investment in proper testing, qualified contractors, and thorough safety measures protects what matters most: the health and safety of workers, occupants, and the community.

Additional resources:

Ready to start your asbestos removal project?

Request a free inspection or call 403-392-2803 to coordinate with Makki Abatement's certified team.